Melting

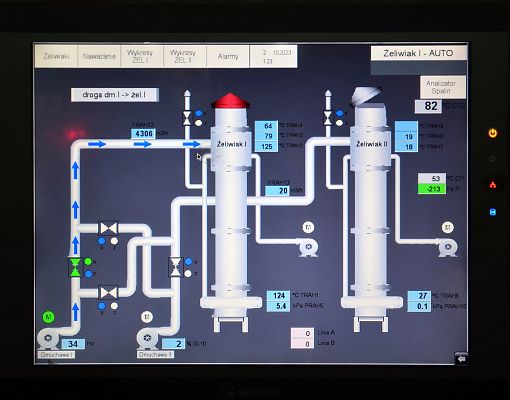

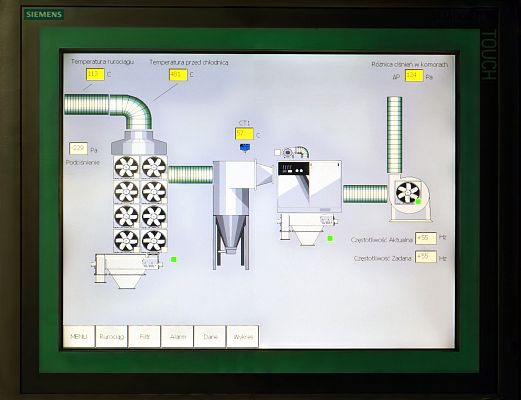

The smelting of cast iron takes place alternatingly, in two shaft furnaces (cupola furnaces) with continuous discharge with a capacity of up to 6 Mg/hour, equipped with a Linde HighJet blast oxygenation system and a dry dust removal installation for the cupolas’ gases. The melting plant is equipped with a computer control system whose features include automatic weighing of charge materials and monitoring and control of the key parameters of the cupola furnace.

We provide a comprehensive service that entails casting design, foundry equipment production, mechanical processing and painting (also in cooperation with our specialised partners), packaging (per the agreed specifications), and delivery.

|

Specification |

Material marking |

|

|---|---|---|

|

PN-EN 1561 |

EN-GJL-150 |

EN-GJL-200 |

|

ISO 185 |

Grade 150 |

Grade 200 |

|

DIN 1691 |

GG 15 |

GG 20 |

|

PN-K-88151 |

P10 |

|

|

Kodex UIC 832V |

||

|

TL/TS0150 |

P15 |

P30 |

We manufacture castings in accordance with procedures established as part of the certified quality management system per the ISO 9001 standard, and the manufacturing cycle is carried out in compliance with occupational health and safety standards and principles for environmental protection, with the use of the best technology available. The company constantly cooperates with industry research institutes and universities in order to improve its products and processes.