Quality assurance

Our company's strategy is invariably associated with attention to quality. We believe that prioritising quality makes us a reliable casting supplier.

All of the processes implemented by the company are supervised and checked per the procedures established as part of the certified quality management system in accordance with the ISO 9001 standard.

The manufacturing processes related to the creation of a casting are monitored and measured by employing the competences of the Laboratory Team.

The checks within the production process, including checks of supplies of materials and raw materials, inter-operation checks (Melting Station, Core Station, Moulding Station, Moulding Sand Processing Station), acceptance checks of castings (after cleaning, processing and packaging) ensure that we maintain the intended parameters and meet the customer's requirements.

Tests

Laboratory tests at the “SPOMEL” Foundry are carried out in the Laboratory Complex, which includes:

- The Chemical and Metallographic Exam Laboratory (which determines the chemical composition of iron alloys using optical emission spectrometry, as well as determines of the microstructure of cast iron),

- The Moulding Materials Testing Laboratory (which tests the moulding and core materials from deliveries and moulding sands in the process),

- The Mechanical Properties Testing Laboratory (which uses the Brinnell method for measuring hardness, as well as does static metal tensile tests, static bending tests of cast iron, load and pull-out strength tests, and impact tests),

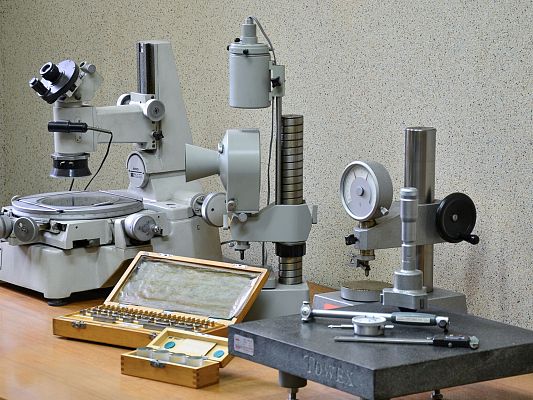

- The Length and Angle Measurement Laboratory (checking the metrological compliance of the measuring instruments, the dimensional control of castings, as well as checking the foundry equipment).